A new look at the MS28042 & ARINC 408 standards.

Avionics Mounts Inc. has been building and selling high quality aircraft instrument mounting clamps for 70 years. (See company history page) Our engineers have designed the majority of avionics mounts in use today. While our old avionics clamp designs may have been considered adequate in the past, today's high powered avionics demand excellent grounding, better holding power, less chance of failure, and the ability to meet the size requirements of the NASM28042 & ARINC 408 standards. Our new designs (Patent #7832699) incorporate all of those features into our new products, while maintaining a low cost.

Some of the major advantages of our new clamp designs are:

- Our new "unibody" design eliminates continuity problems across the band and lug allowing for better grounding of the instrument. This is something that our old designs lacked without brazing one component to the other. This advantage will allow other customers like Bell Helicopter to reduce their inventory and simplify procurement by using four part numbers instead of eight.

- The new design eliminates the weak spot of its predecessors by removing the rivets from the closing mechanism. This assures that all of the torque applied in tighten this clamp, goes to securing the instrument. The advanced closing mechanism in our new design operates on "slides" that are machined into the clamp body, and closing mechanism. This eliminates the problems associated with other clamp designs, where all of the torque applied to close the mount, is transferred through rivets that have a tendency to fail.

- Our new avionics clamps do not require any heat treatment processes which results in less cost, shorter lead times, and a "greener" product. The material starts as 6061-T6 and stays at 6061-T6 through out the whole manufacturing process. There is no annealing or heat treating. Therefore the need to send parts all over the country to meet a customer's "approved processing sources" is eliminated.

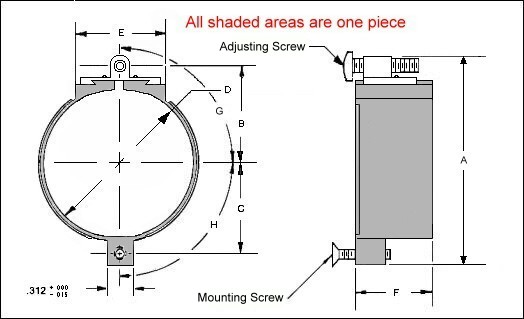

- Our new design meets all dimensional requirements of the NASM28042 (Formerly MS28042) and the ARINC 408A standards. This is where most of our competitor's products fail, they simply do not meet the dimensional requirements of the standards. With our product, there is no need for Material Deviation Requests to allow for the use of "out of tolerance" product.

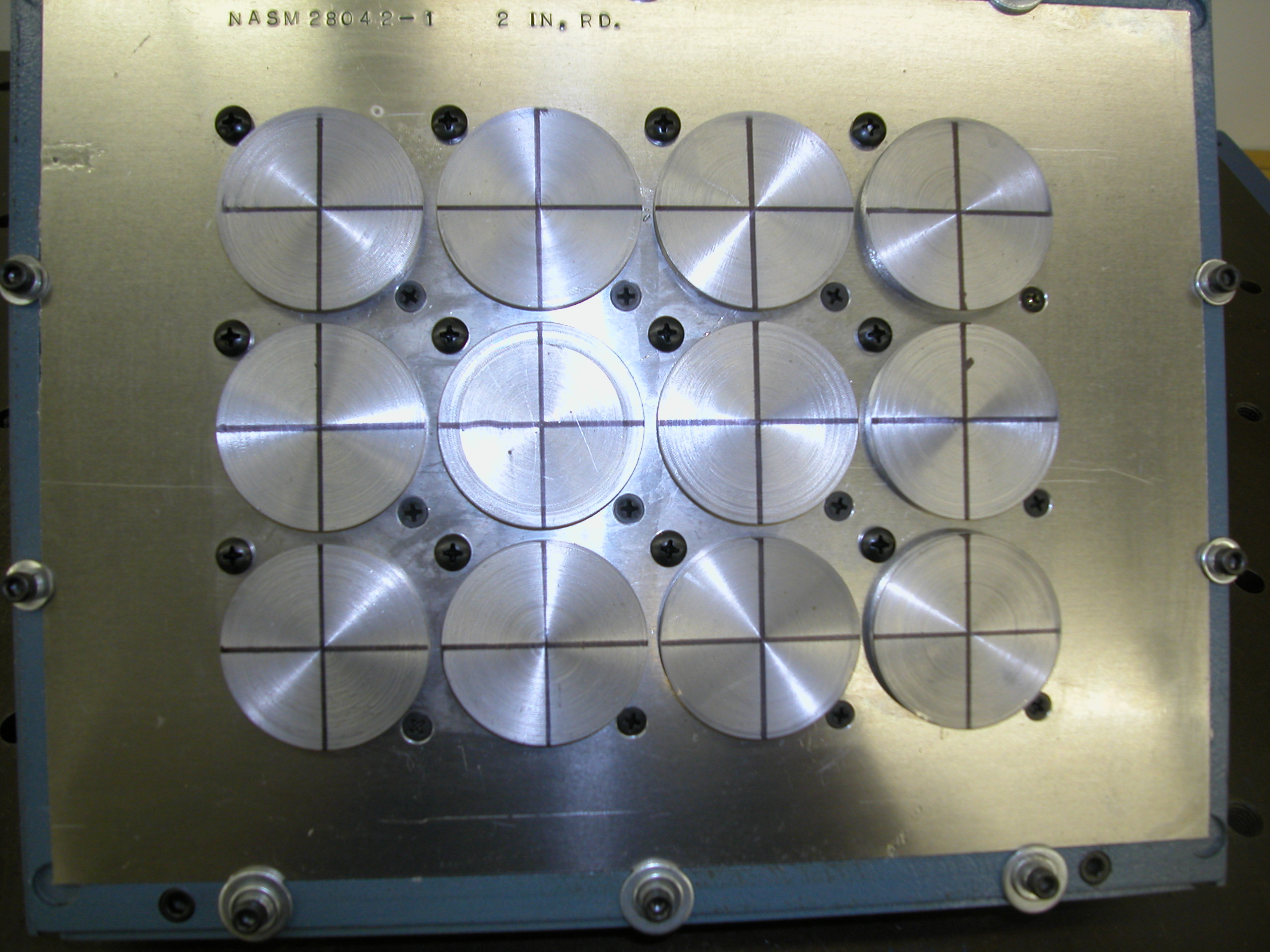

- Per the requirements of the MS28042 standard, every batch of these instrument mounts are vibration tested in house per the requirements of NASM6818.

NASM6818 Vibration Tester

The next generation of MS28042 & ARINC 408A avionics clamps.